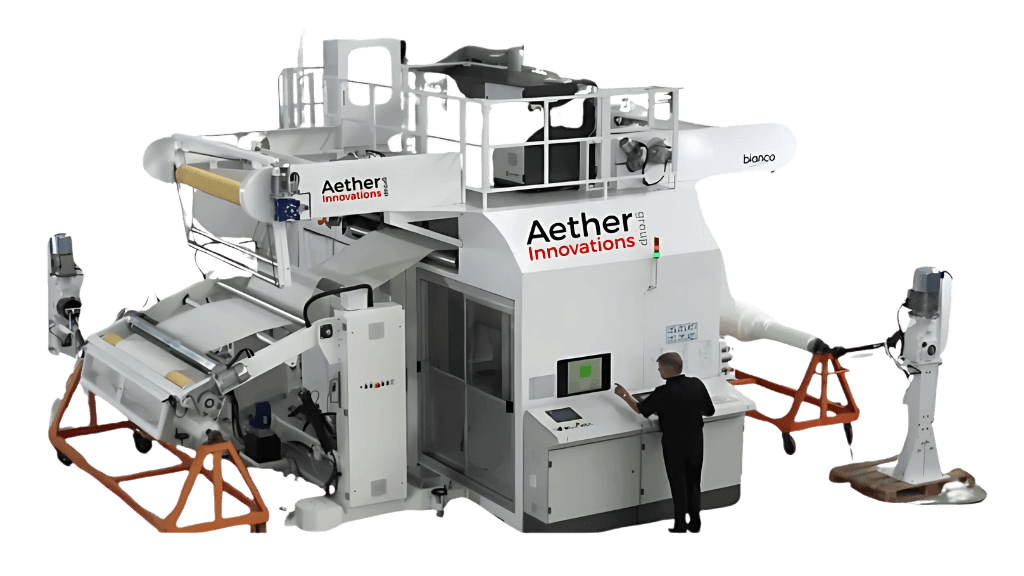

We have developed, designed and implemented waterless textile surface preparation & finishing systems, using our patented MLSE® technology,

MLSE® technology utilizes lasers to bond or sinter fibers at a molecular level, transforming the fabric’s structure without relying on traditional chemical treatments or extensive mechanical processes.

A key benefit of MLSE® technology is its potential to lower environmental impact. By reducing reliance on water, chemicals, and energy commonly used in traditional textile processing, MLSE promotes more sustainable manufacturing practices.

MLSE® is a dry, atmospheric pressure process using gases like Nitrogen, Oxygen, Argon, and Carbon Dioxide. It combines gas plasma and photonic energy to permanently synthesise material on a substrate’s surface without changing its feel. This unique process has non-replicable IP.

The precise nature of laser application allows for tailored modifications of fabric properties such as texture, durability, and overall performance.

This technology is applicable across a diverse array of materials, including natural fibers, synthetic fabrics, and blends, opening doors for innovation in sectors such as fashion, automotive, and technical textiles.

MLSE® is the world’s first patented digital finishing platform, offering solutions for fabric preparation and scouring, improved dyeing capacity, and enhanced print adhesion. It also increases digital printing efficiency and imparts water repellency to fabrics.

The textile industry is one of the most resource-intensive sectors globally, with significant impacts on water, energy consumption, and chemical pollution.

* Ellen MacArthur Foundation, A new textiles economy: Redesigning fashion’s future (2017).

The textile industry is responsible for approximately 10% of global greenhouse gas emissions.

Textile production is estimated to be responsible for about 20% of global clean water pollution from dyeing and finishing products.

Our breakthrough technology of Multiplexed Laser Surface Enhancement (MLSE®) specialized application modifies the surface of textile to PREVENT microfibre shedding from garments during the washing process.

This process does not use any water or chemicals. It provides a possible solution for existing common materials in the apparel industry, including blended fabrics.